Benelux

United Kingdom

India

Slovakia

USA

Germany | EN

Contact

Downloads

Benelux

United Kingdom

India

Slovakia

USA

Benelux

United Kingdom

India

Slovakia

USA

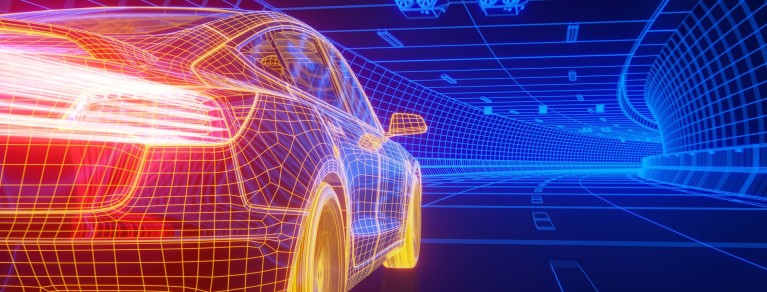

In a wide range of areas,the company offers solutions that perceptibly improve the life span, economic efficiency and comfort of a vehicle. This includes, for example, decoupling elements, ducts, return lines, fluid lines, curved near-engine components and precision bellows.

Our engineering expertise from the initial customer contact to the optimal production design is one of our core strengths. This is what has made us the global market leader in our industry.

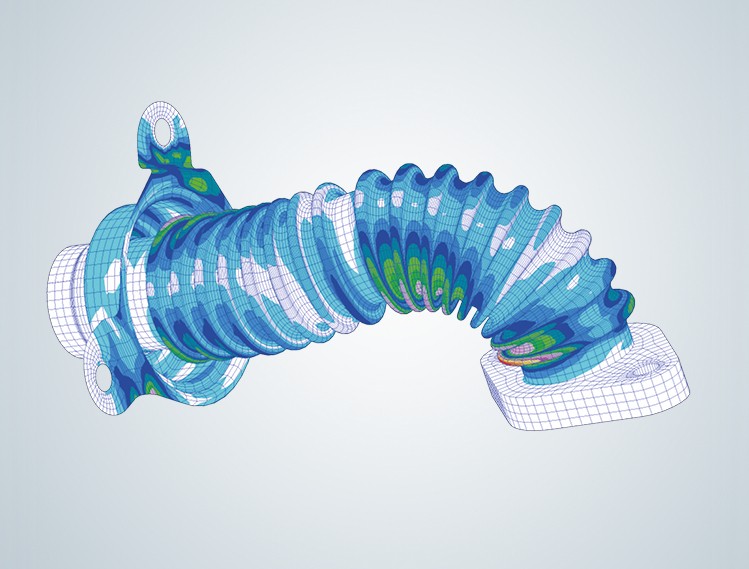

Well over 1000 analysed operational loads and calculation models form the basis for our precise design optimisation. To reach physical tests quickly we have, for example:

We use our experience to support our customers in system design and validation. So we supply production-representative prototypes and calculation models compared with them, whose characteristics are tuned to the system behavior. It is important for us to ensure the function of our products in the system and thus to contribute to an optimal overall result.

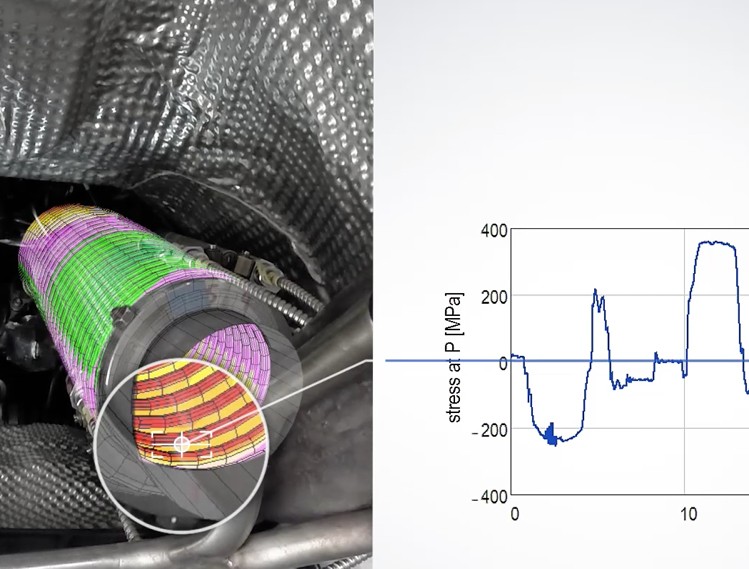

Thanks to many years of experience both in building capable measurement systems as well as in the interpretation of the various customer test tracks and driving manoeuvres we can calculate the lifespan of our components quickly and precisely, allowing us to offer a design optimised for particular applications.

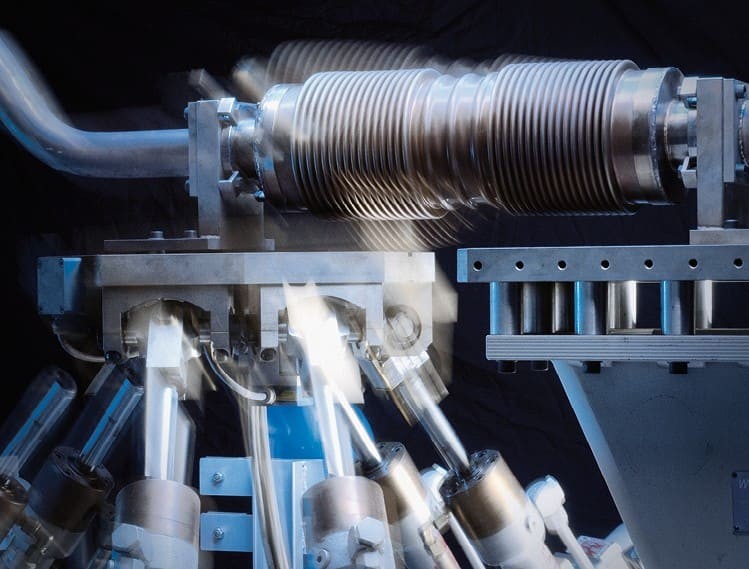

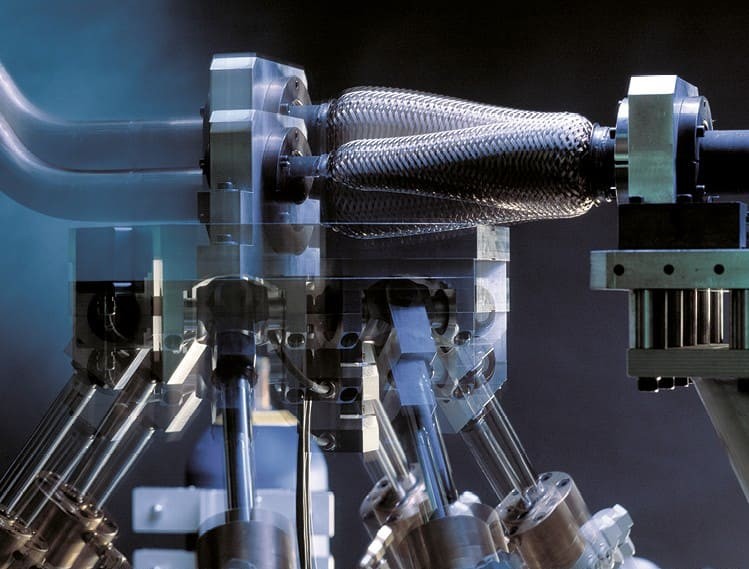

Simulating the life of a vehicle in the shortest possible time requires precise knowledge of the interplay of all relevant operating loads, competence in computational analysis and fast, highly precise test bench technology.

Our calculation and testing methods allow us to represent an entire vehicle life on the test bench within a few days.

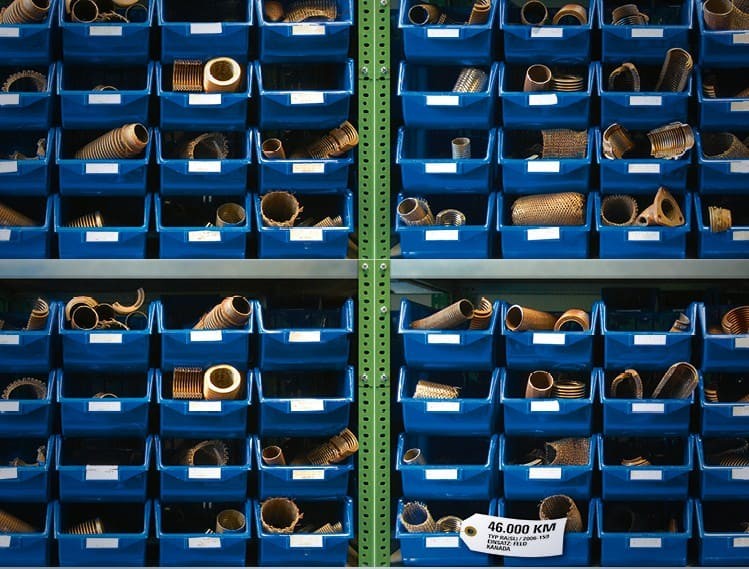

Thanks to the systematic analysis of components after their use in customer testing and in the field, we know the demands placed upon our products very well. A large number of analysed components forms the basis for the world's largest database of returned parts.

We have set up strategic Tech Centres in Europe, Asia and the USA. Each with their prototype construction facilities, their own material laboratories, test grounds and FEM design and calculation capacity.

Our engineers are always with the customer on-site when it comes to finding new possible solutions.

Hybrid, electric motors and fuel cells are currently the most promising new forms of propulsion. With our engineering and process know-how, we are bringing the transformation to the maturity required for series production. We are already implementing solutions for these new applications.

The real art consists in reflecting the real operating data from the road 1 for 1 in the test environment. With our own test programs, we can do this in detail, reproducing a car's entire life in 5 days.

Industry awards are the confirmation of work well done. For example, we were proud to receive the Volkswagen Group Award 2017 in the "Capacity" category, through which we were recognised as one of the Volkswagen Group's best suppliers in 2017. This is one of many awards.